STEP #1 - DEFINE

PROJECT - SIPOC - VOC

Step #1 - DEFINE

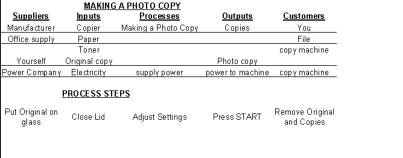

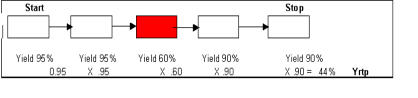

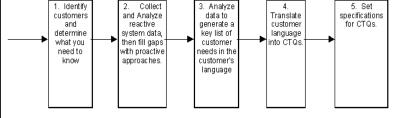

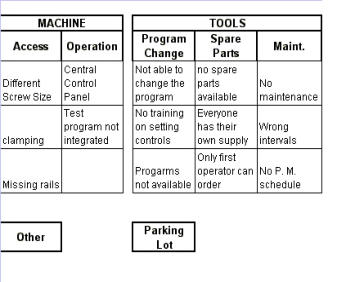

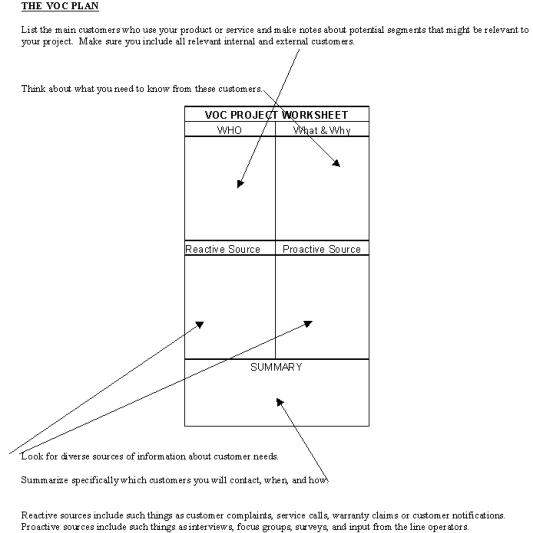

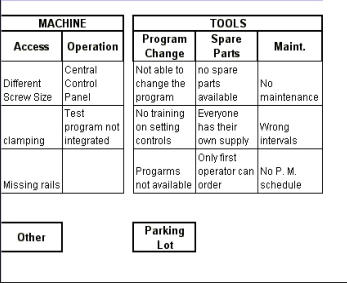

In this phase, you will be setting project goals and boundaries based upon your knowledge of your organization's business goals, customer needs, and the process that needs to be improved to get you to a higher sigma level. The tools that are most commonly used in the Define phase are: 1. Project charter (to include the business case). 2. Stakeholder analysis. 3. SIPOC 4. Rolled Throughput Yield 5. Voice of the customer 6. Affinity Diagram 7. Kano Model 8. Critical-to-Quality (CTQ) treePROJECT CHARTER

The charter is a contract between the organization's leadership and the team created at the onset of the project with the purpose of: · Clarifying what is expected of the team. · Keeping the team focused. · Keeping the team aligned with organizational priorities. · Transferring the project from the champion to the team. The main elements of the Charter are: · Business case (financial impact) · Problem statement · Goal statement · Project scope · Roles of the team members · Milestones/deliverables · Support required and from whom.Business Case - Since most organizations do not have unlimited resources, teams should

be assigned to projects with a significant financial impact. Rough estimates can be used,

and some examples could be:

Reduce inventory levels to reduce capital investment in inventory.

Reduce time-to-market to increase revenues through increased sales.

Reduce equipment downtime to increase capacity and production.

Reduce rejects and rework to decrease material costs rendering a greater ROI

Speed up delivery time to increase revenues.

Reduce set-up time to increase capacity and reduce downtime.

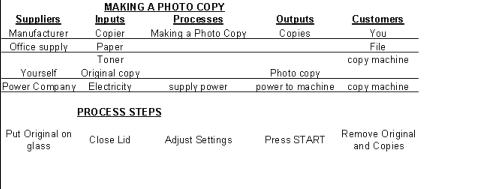

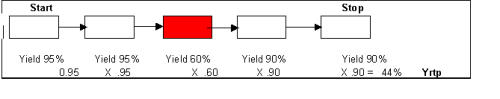

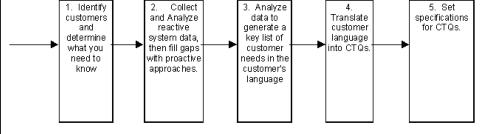

Teams should be aware that these estimates are likely to change as the team finds out more about the problems, constraints, and root cause, and the problem itself becomes more of a focus. It is generally advisable to quantify your anticipated results with someone from the Finance Department. Stakeholder Analysis - A DMAIC project will require a fundamental change in the process, and thus will require an attempt to overcome some form of resistance to a change when the improvement is implemented. Therefore, it is important to identify the stakeholders at the beginning of the plan and develop a communication plan with them. Stakeholders are typically the managers and people who work in the process, the upstream and downstream departments, the customers, the suppliers and finance. Regular communication will create more buy-in, identify better solutions, and avoid potential pitfalls. It is a good idea for the team to develop a "commitment scale" to identify the groups involved or affected by the change, identify the amount of work required to bring the groups to the level of commitment needed for the successful implementation of the change, and to help set priorities and develop effective communication plans. The team should note that not every group needs to be brought to the level of enthusiastic support for successful implementation of the plan. SIPOC A SIPOC is a high-level process map that includes Suppliers, Inputs, Process, Outputs and Customers. Quality is judged based on the output of a process. The quality of the output is improved by analyzing input and process variables. SIPOC is an effective communication tool ensuring that the team members are all viewing the process in the same way. It also informs leadership of exactly what the team is working on, and for that reason, needs to be developed in the beginning or early stages of the methodology. This tool guides the process; the process is mapped at a high level (4-7 steps), and then working from the right side, you identify the customer, the output, the input and the supplier. An example of this process is listed below. Questions that might help with establishing an SIPOC: · PURPOSE - Why does this process exist? · OUTPUTS - What product/service does this process make? · CUSTOMERS - Who uses the products from this process? · INPUTS/SUPPLIERS - Where does the information or material you work on come from? Who are your suppliers? · PROCESS STEPS - What happens at and to each input? How to construct an SIPOC: · Name the process. · Clarify the Start and Stop places of the process. · List key outputs and customers. · List key inputs and suppliers. · Identify, name and place in order the major process steps. Rolled Throughput Yield - Generally if you can identify your steps and your constraints, the calculation of a rolled throughput yield can help you to focus on the problem or bottleneck. An example is given How To Calculate the Rolled Throughput Yield: · Calculate yield for each process step. · Calculate Rolled Throughput Yield (RTY) to establish a baseline for the entire process by multiplying each step yield to the other for an overall (Yield rtp) output. · Revisit your project scope and ensure it emphasizes the problem area. · Significant differences in yield suggest creating a new map for the sub-process with the lowest yield. Voice Of The Customer (VOC) - used to describe the customers' needs and their perceptions of your product or service. The VOC is critical to an organization to: · Decide what products and services to offer. · Identify critical features and specifications for those products and services. · Decide where to focus improvement efforts. · Get a baseline in measure of customer satisfaction to measure improvement against. · Identify key drivers of customer satisfaction The Process for VOC is: · A list of customers and customer segments. · Identification of relevant reactive and proactive sources of data. · Verbal or numerical data that identify customer needs. · Defined Critical-to Quality (CTQs) requirements. · Specifications for each CTQ. It is helpful to summarize these layers of information using an AFFINITY DIAGRAM. AFFINITY DIAGRAM - a tool that organizes language data into relative groups with the emphasis on creative thinking or intuitive thinking. The reason to create an affinity diagram is it: · Encourages breakthrough thinking. · Helps to identify patterns thru scores of data. · Allows you to gather large amounts of language data. · Can be used to organize ideas, issues and opinions. · Encourages ownership of results. When to use an Affinity Diagram: · Analyzing qualitative customer data. · Dealing with complex problems or issues. · Organizing ideas, issues, and opinions. How to Construct an Affinity Diagram: · Statements or ideas are written on individual cards or post-it notes. · Notes are clustered based on intuition, not logic. After placing notes in a somewhat categorized fashion, if you disagree with a note's placement, move it. If you disagree with where someone else moves a note, either move it back or create a "parking lot" to discuss further. · Clusters of notes are given titles, which identify themes. There can be several layers of clusters. · One note can be a cluster if it is not related to other topics. An example is offered below: KANO Model - Noriaki Kano developed a model for understanding customer requirements and developed a three-category model of customer needs: Must Be - These needs are expected by the customer. If they are unfulfilled, the customer will be dissatisfied, but even if they are completely fulfilled, the customer would not be particularly satisfied. More Is Better - These needs have a linear effect on customer satisfaction. The more these needs are met, the more satisfied the customer will be. Delighters - These needs do not cause dissatisfaction when not present but satisfy the customer when they are present. The combined KANO Model and VOC: · Must be characteristics that are generally taken for granted unless they are absent. · Customers generally discuss or bring up issues related to More is Better characteristics. · Delighters are generally not mentioned, since the customers are not dissatisfied with the absence thereof. CTQ Tree - a tool that aids in translating customer language into quantified requirements for our product/service. Why create a CTQ Tree: · Translates broad customer requirements into specific critical-to-quality (CTQ) requirements. · Helps the team to move from high-level to detail specifications. · Ensures that all aspects of the need are identified. When to use a CTQ Tree: · Unspecified customer requirements · Complex, broad needs Setting Specifications for CTQs: In manufacturing, specification limits often come from technical or mechanical requirements, otherwise, the base specification limits on data about customer needs set the specifications where customer satisfaction starts to fall off noticeably. Specifications can either be one-sided or two-sided. If there is a single value that the process output should not go above or below, it is a single-sided specification. If you can define both a lower and upper boundary, you have two-sided specifications. By following the five-step VOC data collection process, you can help ensure that you have understood the current situation from the customer's perspective. An example of a CTQ tree is as follows: SUMMARY OF PHASE I - DESIGN Upon completion of this First Step Level, you have seen the following and should be able to report to your Champion: · Why this project is important. · What business goals the project must achieve to be considered successful. · Who the players are on the project (sponsors, advisors, team leader, team members). · What limitations have been placed on the project (budget, time, resources). · What key process is involved (including suppliers, input, outputs and customers). · What the current process yield is. · What the customer requirements or specifications are.

© The Quality Web, authored by Frank E. Armstrong, Making Sense Chronicles - 2003 - 2016

STEP #1 - DEFINE

PROJECT - SIPOC - VOC

Step #1 - DEFINE

In this phase, you will be setting project goals and boundaries based upon your knowledge of your organization's business goals, customer needs, and the process that needs to be improved to get you to a higher sigma level. The tools that are most commonly used in the Define phase are: 1. Project charter (to include the business case). 2. Stakeholder analysis. 3. SIPOC 4. Rolled Throughput Yield 5. Voice of the customer 6. Affinity Diagram 7. Kano Model 8. Critical-to-Quality (CTQ) treePROJECT CHARTER

The charter is a contract between the organization's leadership and the team created at the onset of the project with the purpose of: · Clarifying what is expected of the team. · Keeping the team focused. · Keeping the team aligned with organizational priorities. · Transferring the project from the champion to the team. The main elements of the Charter are: · Business case (financial impact) · Problem statement · Goal statement · Project scope · Roles of the team members · Milestones/deliverables · Support required and from whom.Business Case - Since most organizations do not

have unlimited resources, teams should be

assigned to projects with a significant financial

impact. Rough estimates can be used, and some

examples could be:

Reduce inventory levels to reduce capital

investment in inventory.

Reduce time-to-market to increase revenues

through increased sales.

Reduce equipment downtime to increase capacity

and production.

Reduce rejects and rework to decrease material

costs rendering a greater ROI

Speed up delivery time to increase revenues.

Reduce set-up time to increase capacity and

reduce downtime.

Teams should be aware that these estimates are likely to change as the team finds out more about the problems, constraints, and root cause, and the problem itself becomes more of a focus. It is generally advisable to quantify your anticipated results with someone from the Finance Department. Stakeholder Analysis - A DMAIC project will require a fundamental change in the process, and thus will require an attempt to overcome some form of resistance to a change when the improvement is implemented. Therefore, it is important to identify the stakeholders at the beginning of the plan and develop a communication plan with them. Stakeholders are typically the managers and people who work in the process, the upstream and downstream departments, the customers, the suppliers and finance. Regular communication will create more buy-in, identify better solutions, and avoid potential pitfalls. It is a good idea for the team to develop a "commitment scale" to identify the groups involved or affected by the change, identify the amount of work required to bring the groups to the level of commitment needed for the successful implementation of the change, and to help set priorities and develop effective communication plans. The team should note that not every group needs to be brought to the level of enthusiastic support for successful implementation of the plan. SIPOC A SIPOC is a high-level process map that includes Suppliers, Inputs, Process, Outputs and Customers. Quality is judged based on the output of a process. The quality of the output is improved by analyzing input and process variables. SIPOC is an effective communication tool ensuring that the team members are all viewing the process in the same way. It also informs leadership of exactly what the team is working on, and for that reason, needs to be developed in the beginning or early stages of the methodology. This tool guides the process; the process is mapped at a high level (4-7 steps), and then working from the right side, you identify the customer, the output, the input and the supplier. An example of this process is listed below. Questions that might help with establishing an SIPOC: · PURPOSE - Why does this process exist? · OUTPUTS - What product/service does this process make? · CUSTOMERS - Who uses the products from this process? · INPUTS/SUPPLIERS - Where does the information or material you work on come from? Who are your suppliers? · PROCESS STEPS - What happens at and to each input? How to construct an SIPOC: · Name the process. · Clarify the Start and Stop places of the process. · List key outputs and customers. · List key inputs and suppliers. · Identify, name and place in order the major process steps. Rolled Throughput Yield - Generally if you can identify your steps and your constraints, the calculation of a rolled throughput yield can help you to focus on the problem or bottleneck. An example is given How To Calculate the Rolled Throughput Yield: · Calculate yield for each process step. · Calculate Rolled Throughput Yield (RTY) to establish a baseline for the entire process by multiplying each step yield to the other for an overall (Yield rtp) output. · Revisit your project scope and ensure it emphasizes the problem area. · Significant differences in yield suggest creating a new map for the sub-process with the lowest yield. Voice Of The Customer (VOC) - used to describe the customers' needs and their perceptions of your product or service. The VOC is critical to an organization to: · Decide what products and services to offer. · Identify critical features and specifications for those products and services. · Decide where to focus improvement efforts. · Get a baseline in measure of customer satisfaction to measure improvement against. · Identify key drivers of customer satisfaction The Process for VOC is: · A list of customers and customer segments. · Identification of relevant reactive and proactive sources of data. · Verbal or numerical data that identify customer needs. · Defined Critical-to Quality (CTQs) requirements. · Specifications for each CTQ. It is helpful to summarize these layers of information using an AFFINITY DIAGRAM. AFFINITY DIAGRAM - a tool that organizes language data into relative groups with the emphasis on creative thinking or intuitive thinking. The reason to create an affinity diagram is it: · Encourages breakthrough thinking. · Helps to identify patterns thru scores of data. · Allows you to gather large amounts of language data. · Can be used to organize ideas, issues and opinions. · Encourages ownership of results. When to use an Affinity Diagram: · Analyzing qualitative customer data. · Dealing with complex problems or issues. · Organizing ideas, issues, and opinions. How to Construct an Affinity Diagram: · Statements or ideas are written on individual cards or post-it notes. · Notes are clustered based on intuition, not logic. After placing notes in a somewhat categorized fashion, if you disagree with a note's placement, move it. If you disagree with where someone else moves a note, either move it back or create a "parking lot" to discuss further. · Clusters of notes are given titles, which identify themes. There can be several layers of clusters. · One note can be a cluster if it is not related to other topics. An example is offered below: KANO Model - Noriaki Kano developed a model for understanding customer requirements and developed a three-category model of customer needs: Must Be - These needs are expected by the customer. If they are unfulfilled, the customer will be dissatisfied, but even if they are completely fulfilled, the customer would not be particularly satisfied. More Is Better - These needs have a linear effect on customer satisfaction. The more these needs are met, the more satisfied the customer will be. Delighters - These needs do not cause dissatisfaction when not present but satisfy the customer when they are present. The combined KANO Model and VOC: · Must be characteristics that are generally taken for granted unless they are absent. · Customers generally discuss or bring up issues related to More is Better characteristics. · Delighters are generally not mentioned, since the customers are not dissatisfied with the absence thereof. CTQ Tree - a tool that aids in translating customer language into quantified requirements for our product/service. Why create a CTQ Tree: · Translates broad customer requirements into specific critical-to-quality (CTQ) requirements. · Helps the team to move from high-level to detail specifications. · Ensures that all aspects of the need are identified. When to use a CTQ Tree: · Unspecified customer requirements · Complex, broad needs Setting Specifications for CTQs: In manufacturing, specification limits often come from technical or mechanical requirements, otherwise, the base specification limits on data about customer needs set the specifications where customer satisfaction starts to fall off noticeably. Specifications can either be one-sided or two-sided. If there is a single value that the process output should not go above or below, it is a single-sided specification. If you can define both a lower and upper boundary, you have two-sided specifications. By following the five-step VOC data collection process, you can help ensure that you have understood the current situation from the customer's perspective. An example of a CTQ tree is as follows: SUMMARY OF PHASE I - DESIGN Upon completion of this First Step Level, you have seen the following and should be able to report to your Champion: · Why this project is important. · What business goals the project must achieve to be considered successful. · Who the players are on the project (sponsors, advisors, team leader, team members). · What limitations have been placed on the project (budget, time, resources). · What key process is involved (including suppliers, input, outputs and customers). · What the current process yield is. · What the customer requirements or specifications are.

© The Quality Web, authored by Frank E. Armstrong, Making Sense

Chronicles - 2003 - 2016