© The Quality Web, authored by Frank E. Armstrong, Making Sense Chronicles - 2003 - 2016

Lesson #4 - Tool #1 - The Check Sheet

Tool #1 - The Check Sheet

As previously mentioned, the intent and purpose of collecting data is to either control the production process, to see

the relationship between cause-and-effect, or for the continuous improvement of those processes that produce any

type of defect or nonconforming product. A Check Sheet is used for the purpose of collecting data to compile in such

a way as to be easily used, understood and analyzed automatically. The Check Sheet, as it is being completed,

actually becomes a graphical representation of the data you are collecting, thus you do NOT need any computer

software, or spreadsheet to record the data. It can be simply done with pencil and paper! Check sheets have the

following main functions:

1.

Production process distribution checks - where the distribution lies.

2.

Defective item checks - to determine what kind of defects exist in the process.

3.

Defect location checks - to determine where the common defects on a part are located.

4.

Defective cause checks - type of defect and thus validate the cause thereof.

5.

Check-up confirmation checks - final phase of assembly to check the finished product or work.

The methods that we will concentrate on and utilize here will be for Production Process distribution and defective

item checks. We will discuss the use and relevance of each individually.

Defective Item Check Sheet

In order to reduce the number of defectives produced, it is necessary to know what kind of defects were produced

and the percentage in relation to production. Since every defect has a different cause, it is useless to just list the total

number of defects, therefore, we have to find the number of defects caused by each category, and then we have to

decide the appropriate action to take to resolve those defects. The appropriate action to take is to pick the top two or

three problem areas, and then focus to resolve them.

In our example, we have charted some defects from an alternator production line. (To view our example please click

HERE). Whenever a defect was discovered, the operator would make an entry in the appropriate column, an "X",

check mark or merely a single line for each occurrence. At the end of the day, it can be easily determined what the

main problem was for that day just by looking at the graph that was created from the recorded marks. If this is done

every day, and on every shift, over the course of a week we can tell what the common problems were, and what

problems seemed to be our biggest headache that requires our primary focus.

However, it is worth noting that the defects attained on one line, may not be the same as those encountered on

another line and similar production line. It may also be that the defects experienced on the day shift, may not be the

same defects experienced on the night shift, on the same line and with the same product. Different people, different

products, time and temperature are all factors that could cause a different set of circumstances for defects to occur.

For that reason, each shift or each line, should have it's own study performed.

Once the shift was over and the totals are tallied, you can see from our example that we had two main problems to

focus on. These totals, taken from the 8 main categories, will be charted in a Pareto chart, as you will see when you

visit the Pareto lesson.

Production Process Distribution

The size, weight, or diameter of parts, for example, are known as "continuous data". In a process where these types

of data are gathered, the distribution they provide will often resemble a Histogram (Histogram is Tool #3). A

histogram can be used to investigate the distribution of the process characteristics, and the average value can be

calculated.

If you click HERE, you can see a sample Production Check Sheet.

In this sample sheet, we measured torque readings. The spec limit is 2.2Nm ± .5. From the example sheet, you should

see two dark vertical lines, on the left side it is labeled LSL (Lower Spec Limit) which indicates the 2.2 - .5, or 1.7. On

the right side, another dark line marked USL (Upper Spec Limit) which indicates the 2.2 + .5, or 2.7. All product

readings, or torque readings in this example, that conform (actually good product), need to fall within these limit

boundaries. Anything that is measured outside these limits is termed "Non-Conforming" since they are not within

proper specification limits.

Every time a measurement was taken, an "X", or check mark, was made on the check sheet. From this sample sheet,

you can see where most of the torque readings lie, the consistency of the distribution, and how many are actually

outside the spec limit. What has also been created here on this Check Sheet is a "Histogram". We will discuss

Histograms in a later lesson. Right now, what is important to note from this example chart is that we do not have a

good stable process. The distribution is widespread and not well centered between the specification limits. The

distribution has dual peaks, or is what is known as "bi-modal".

Bi-modal means that there are two points where most of the readings taken are charted, or that is has two peaks.

This means the frequency of readings rises and falls twice, rather than a more proper and even distribution with one

peak.

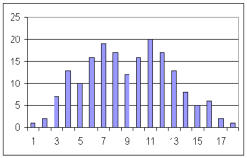

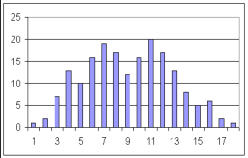

To illustrate further, I have taken the same data and plotted that in a bar graph to show you the physical appearance

just as if it were plotted using Excel. You can see that this looks much like the hand drawn chart that was made in our

example. Notice also that you can see two distinct "peaks" separated by less frequent readings in the middle of the

two peaks.

BLANK PRODUCTION FORMS

For a Blank copy of the Production Process Check Sheet in Excel, Click ON THIS LINK.

For a Blank copy of the Defective Item Check Sheet in Excel, Click ON THIS LINK.

© The Quality Web, authored by Frank E. Armstrong, Making Sense

Chronicles - 2003 - 2016

Lesson #4 - Tool #1 - Check Sheet

Tool #1 - The Check Sheet

As previously mentioned, the intent and purpose of

collecting data is to either control the production process,

to see the relationship between cause-and-effect, or for

the continuous improvement of those processes that

produce any type of defect or nonconforming product. A

Check Sheet is used for the purpose of collecting data to

compile in such a way as to be easily used, understood

and analyzed automatically. The Check Sheet, as it is being

completed, actually becomes a graphical representation of

the data you are collecting, thus you do NOT need any

computer software, or spreadsheet to record the data. It

can be simply done with pencil and paper! Check sheets

have the following main functions:

1.

Production process distribution checks - where the

distribution lies.

2.

Defective item checks - to determine what kind of

defects exist in the process.

3.

Defect location checks - to determine where the

common defects on a part are located.

4.

Defective cause checks - type of defect and thus

validate the cause thereof.

5.

Check-up confirmation checks - final phase of

assembly to check the finished product or work.

The methods that we will concentrate on and utilize here

will be for Production Process distribution and defective

item checks. We will discuss the use and relevance of each

individually.

Defective Item Check Sheet

In order to reduce the number of defectives produced, it is

necessary to know what kind of defects were produced

and the percentage in relation to production. Since every

defect has a different cause, it is useless to just list the

total number of defects, therefore, we have to find the

number of defects caused by each category, and then we

have to decide the appropriate action to take to resolve

those defects. The appropriate action to take is to pick the

top two or three problem areas, and then focus to resolve

them.

In our example, we have charted some defects from an

alternator production line. (To view our example iplease

click HERE). Whenever a defect was discovered, the

operator would make an entry in the appropriate column,

an "X", check mark or merely a single line for each

occurrence. At the end of the day, it can be easily

determined what the main problem was for that day just

by looking at the graph that was created from the

recorded marks. If this is done every day, and on every

shift, over the course of a week we can tell what the

common problems were, and what problems seemed to

be our biggest headache that requires our primary focus.

However, it is worth noting that the defects attained on

one line, may not be the same as those encountered on

another line and similar production line. It may also be

that the defects experienced on the day shift, may not be

the same defects experienced on the night shift, on the

same line and with the same product. Different people,

different products, time and temperature are all factors

that could cause a different set of circumstances for

defects to occur. For that reason, each shift or each line,

should have it's own study performed.

Once the shift was over and the totals are tallied, you can

see from our example that we had two main problems to

focus on. These totals, taken from the 8 main categories,

will be charted in a Pareto chart, as you will see when you

visit the Pareto lesson.

Production Process Distribution

The size, weight, or diameter of parts, for example, are

known as "continuous data". In a process where these

types of data are gathered, the distribution they provide

will often resemble a Histogram (Histogram is Tool #3). A

histogram can be used to investigate the distribution of

the process characteristics, and the average value can be

calculated.

If you click HERE, you can see a sample Production Check

Sheet.

In this sample sheet, we measured torque readings. The

spec limit is 2.2Nm ± .5. From the example sheet, you

should see two dark vertical lines, on the left side it is

labeled LSL (Lower Spec Limit) which indicates the 2.2 - .5,

or 1.7. On the right side, another dark line marked USL

(Upper Spec Limit) which indicates the 2.2 + .5, or 2.7. All

product readings, or torque readings in this example, that

conform (actually good product), need to fall within these

limit boundaries. Anything that is measured outside these

limits is termed "Non-Conforming" since they are not

within proper specification limits.

Every time a measurement was taken, an "X", or check

mark, was made on the check sheet. From this sample

sheet, you can see where most of the torque readings lie,

the consistency of the distribution, and how many are

actually outside the spec limit. What has also been created

here on this Check Sheet is a "Histogram". We will discuss

Histograms in a later lesson. Right now, what is important

to note from this example chart is that we do not have a

good stable process. The distribution is widespread and

not well centered between the specification limits. The

distribution has dual peaks, or is what is known as "bi-

modal".

Bi-modal means that there are two points where most of

the readings taken are charted, or that is has two peaks.

This means the frequency of readings rises and falls twice,

rather than a more proper and even distribution with one

peak.

To illustrate further, I have taken the same data and

plotted that in a bar graph to show you the physical

appearance just as if it were plotted using Excel. You can

see that this looks much like the hand drawn chart that

was made in our example. Notice also that you can see

two distinct "peaks" separated by less frequent readings in

the middle of the two peaks.

For a Blank copy of the Defective Item Check Sheet in

Excel, Click ON THIS LINK.

For a Blank copy of the Production Process Check Sheet in

Excel, Click ON THIS LINK

BLANK PRODUCTION FORMS